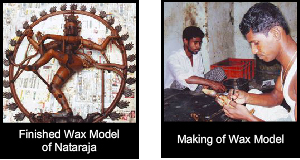

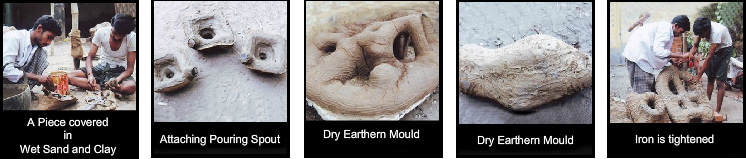

One of the most recognised artwork in the world; the Chola bronze statue involves demanding handwork. Originally considered as temple art,it

is handled by artisans with extraordinary care and devotion. The Shilpa Shastra is still referred as the basic guide to achieve perfect

anatomical proportions for the sculptures. In India,the traditional artisans are concentrated in and around the Kumbakonam,district Tamil Nadu.

Astoundingly they still employ the same lost wax process used in the Chola period.

Mr.Ln.Rajagopal is one mastercraftsmen from the traditional viswakarma community. His vast experience in bronze sheet works and temple needs

manufacturing helps him run the production unit “sri raja silpalaya” Our specialties are exquisite sheet metal works any size any shape and

complicate details. We do sheet covering for engraved, embossed,with high relief work. We undertake sheet works in gold,silver and bronze

to gopurams,rathams,kodimaram,doors,vagnam and even temple roofings.

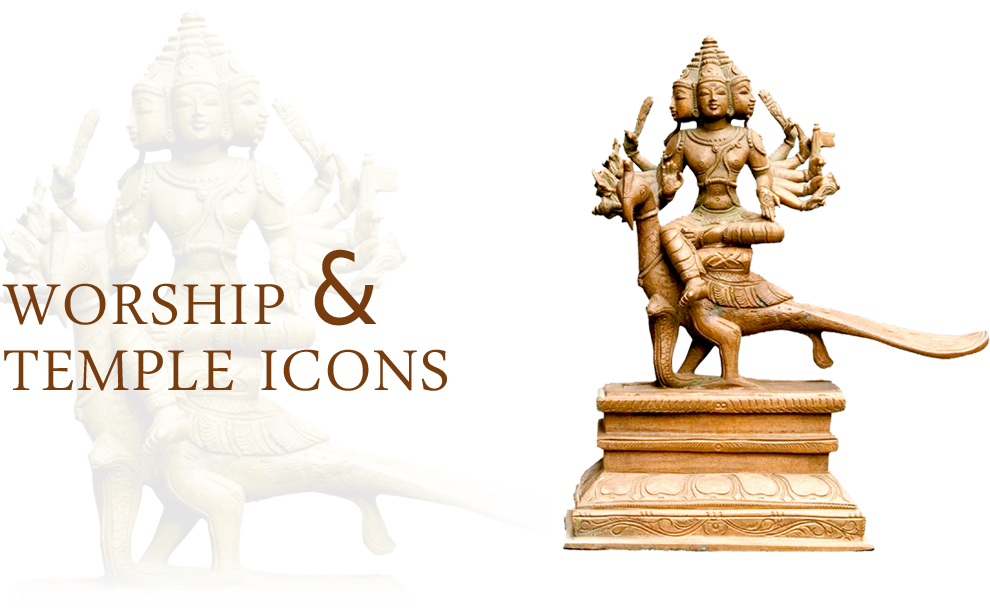

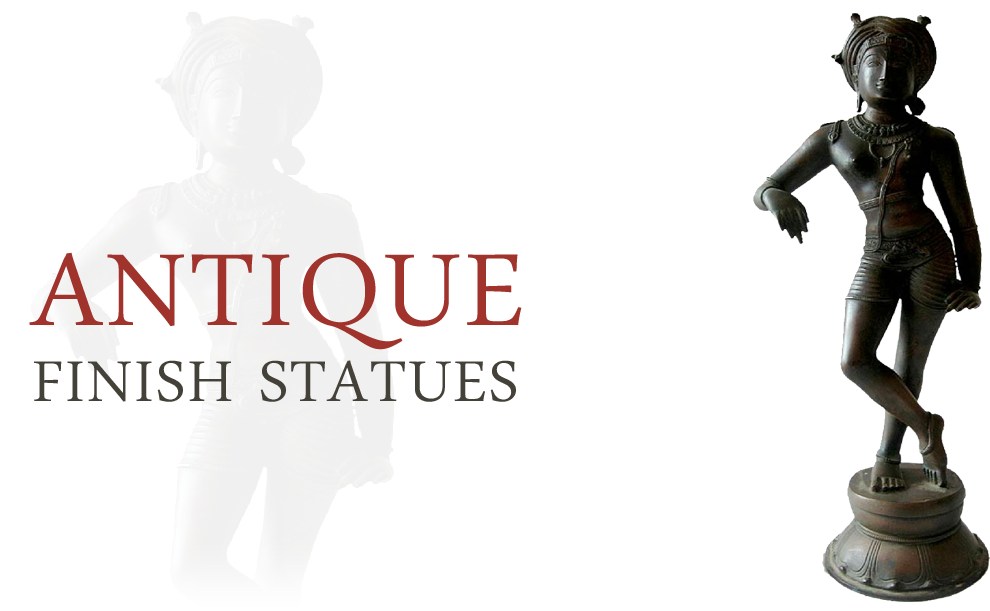

We have displayed our gallery right from icons, ornamental lamps,sheet works and stone works. We thank all our clients and well wishers who

made us renouned temple need manufacturer in kumbakonam. We have opened new showroom near darasuram temple near our factory